It is an essential enabler of the energy transition due to its light-weight properties and conductivity – only bettered by copper (and silver) (but since its lower cost it can replace copper in overhead transmission applications as well as cabling in solar power farms and most wind farms – apart from deep sea).

However, mining comes with an environmental and carbon footprint, and the aluminium industry is focused on reducing it. A greener world means investing in innovative solutions to decarbonise and committing to long-term plans for reducing the environmental impact of mines.

A sustainable mining operation maintains the natural capital and protects and restores the biodiversity of the area through sound environmental management systems. This commitment starts before the mining begins, when operators carry out an environmental impact assessment. This covers everything from the impact on freshwater uses, assessing the effect on flora and fauna, and predicting dust and noise pollution.

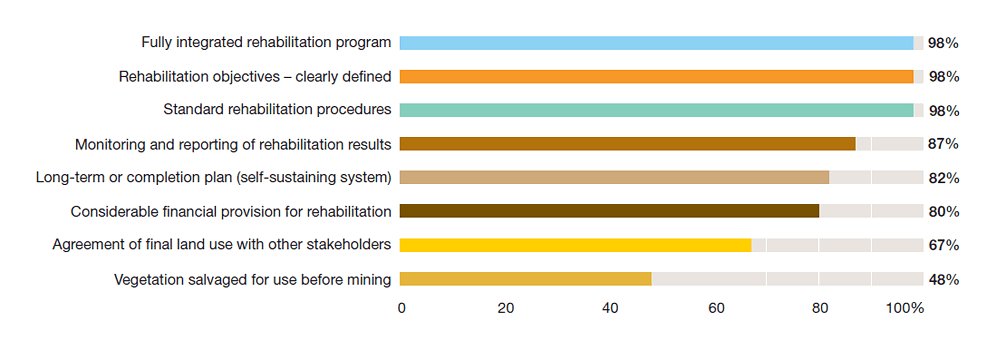

Processes are then put in place to mitigate the environmental and social impacts. These include controlling dust levels through watering, road maintenance and speed limits, the construction of settling ponds, and the rehabilitation of the mined area after the closure of the mine. A successful rehabilitation and environmental programme ensures that bauxite mining does not compromise other long-term land uses.

As well as minimising the impact on the local environment and community, it is also imperative to minimise the global impact by reducing emissions and using energy more efficiently. There are several strategies involved in achieving this:

- Using more energy-efficient mining equipment and trucks;

- Improving the maintenance of mining and transport machinery;

- Optimising truck cycle times and reducing idling and waiting times to improve equipment efficiency;

- Reducing long-haul distances for overburden storage;

- Using downhill regenerative cable belt conveyors to transport bauxite;

- Changing to lower-emission fuels such as natural gas, hydrogen, and electrification, where possible.

- Installing renewable energy generation for auxiliary and fleet recharging purposes.

A sustainable mining operation maintains the natural capital of the area in which it is located through sound environmental management systems. Successful rehabilitation and environmental management ensures that bauxite mining is a temporary land use that does not compromise other long term land uses.

Along with the land required for infrastructure, globally only around 50 km² is newly mined for bauxite every year; this is equivalent to around one square metre disturbed per tonne of aluminium produced.