Casting, extrusion, and rolling are the major methods for fabricating aluminium, but other processes can shape, bend, bow, weld, and cut metal. Let’s explore other fabrication methods that show just how versatile aluminium is.

Machining

Many machining operations that apply to steel can also apply to aluminium alloys, but with one advantage: it is considerably faster to machine aluminium alloys. This can be done through drilling, milling, thread cutting, and punching.

Cold Forming

Like machining, the equipment and methods used to bend aluminium are similar to steel, and forging is often used to form unique components, particularly for the car industry. However, it is delicate work: while cold forming increases the strength of aluminium, it also decreases its elongation capacity.

Cutting

There are three main methods for cutting:

- Plasma gas cutting: Rapid, versatile, and highly effective. While it isn’t suitable for complex extruded profiles, it is perfect for plate material.

- Shearing: Used for precision cutting where clean edges are needed, shearing is often the method of choice on plate, sheet, and flat bar profiles.

- Sawing: Fast and versatile, band and circular saws are used for cutting.

- Special disks: Used for minor cutting operations, such as preparing weld grooves.

Whether it’s smelting, casting, extruding, rolling, machining, or cutting, aluminium’s low density, resistance to corrosion, and malleability make it the most versatile metal on the planet.

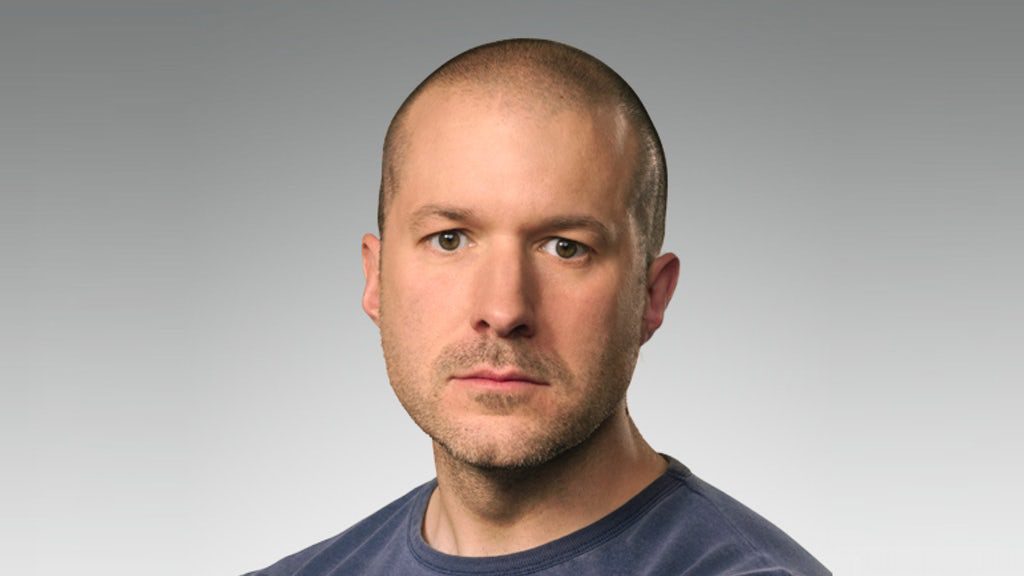

Chief Design Officer

Apple

“The only way to make the MacBook Pro unibody was to machine it from a single piece of aluminium.”

Apple MacBook Pro Aluminum Unibody Design Video