A variety of alloys, both wrought and casting, are produced by remelters and refiners.

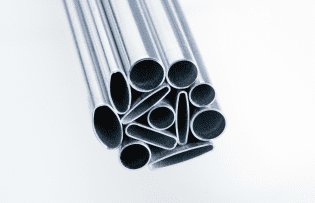

Wrought alloys are mostly produced through remelting of new scrap or of old scrap with known and well defined compositions, such as used beverage cans. Depending on the origins of the scrap, remelted wrought alloys remain largely in the same production process as input material for either rolled products or extruded products.

Casting alloys are the products of the refining process using mixed new and/or old scrap. Some refiners also produce a small amount of aluminium alloys as de-oxidation agent for the steel making industry.

As input material to the foundries, casting alloys are processed through pressure die-casting, gravity die-casting and sand casting into various cast products. One of the major sectors using aluminium castings is the automotive industry and applications include fuel engine blocks, cylinder heads, transmission cases, energy absorbers, safety parts, suspension parts, components of steering system and wheels.

Aluminium castings are also widely used in building and construction as components of equipment and on-site facilities, and in the engineering sectors as components of both heavy and fine machines and tools.