Anodes are critical to smelting because they are used to conduct electricity during the reduction process, producing aluminium. Anodes are large carbon blocks, and how they are used depends on which smelting technology is being used: Søderberg or prebake.

Søderberg smelters are far less common than prebake smelters and have mostly been phased out due to their higher environmental impact. They use a continuously created anode, which is made by adding raw material, usually called pitch, to the top of the pot – a cell where the electrolysis takes place. The heat generated by the reduction process is used to bake the pitch into the carbon form required for reaction with alumina.

Prebake anode production

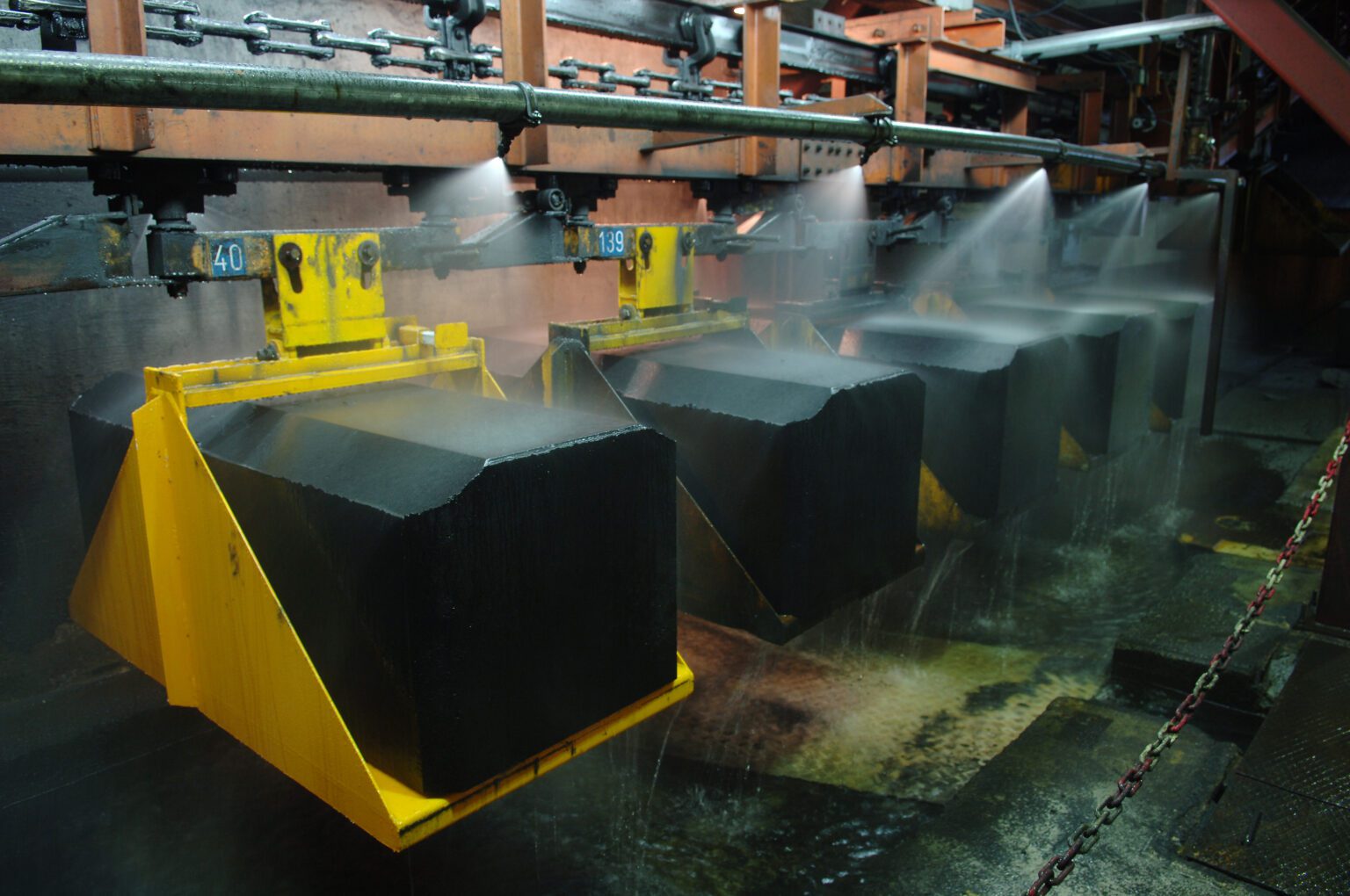

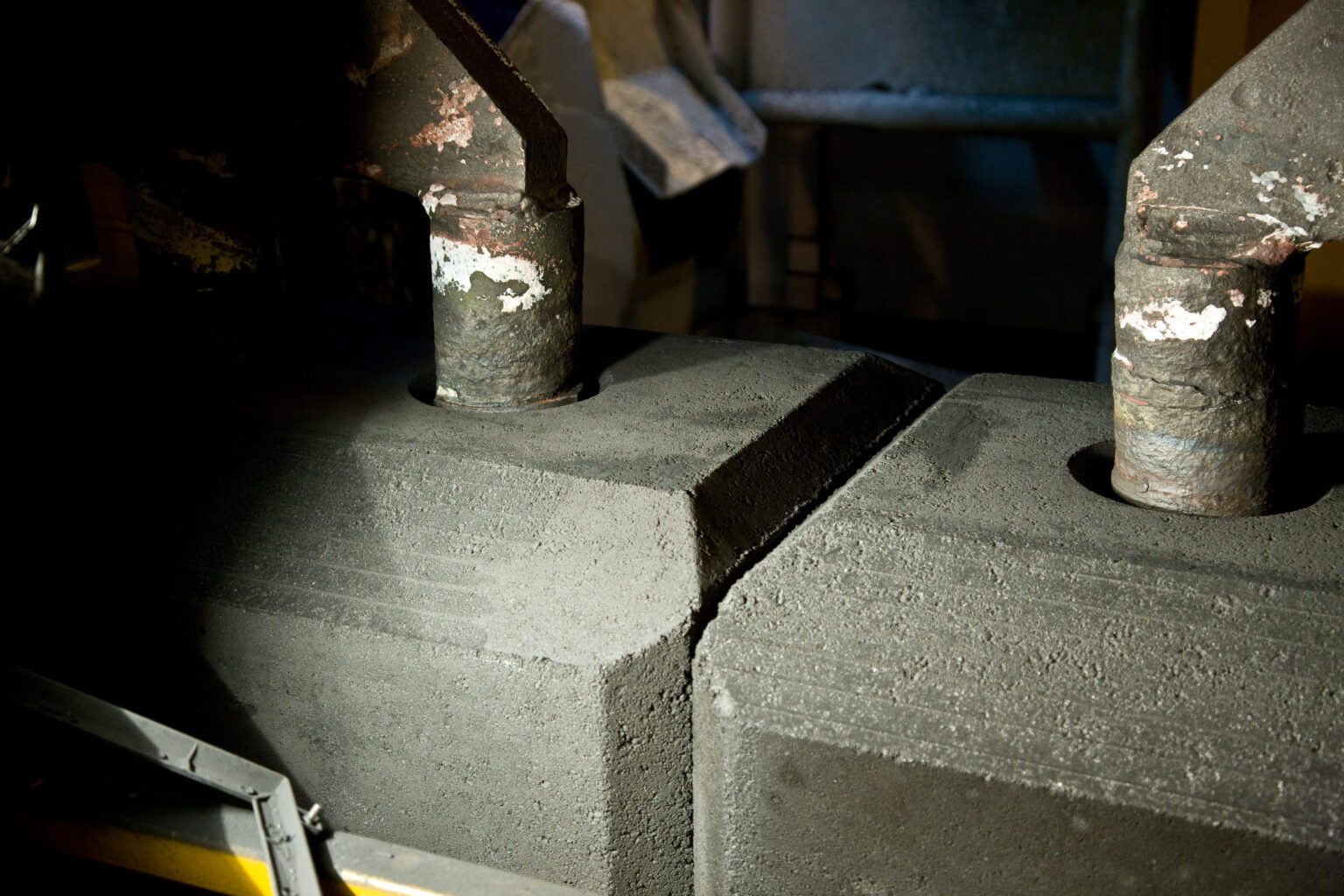

Due to its efficiency, prebake smelting technology is used in over 90% of aluminium production worldwide. Prebake anodes are made from petroleum coke, pitch, and the recycled ends of anodes. These materials are mixed together, poured into moulds and, after forming, baked into a solid block of carbon at a temperature of 1120°C.

The solid blocks of carbon are fused to a steel rod that has two important functions: lowering the blocks into the pot and conducting the electrical current. Finally, these blocks of carbon are transported to the smelter potroom, where they are placed in the reduction cells for the next step in the process.

“Without carbon, without anodes, we wouldn’t be able to realise the potential of aluminium metal.”