The intrinsic beauty of mill finish aluminium and its flexibility in fabrication create the elegancy of this regional airport with a small budget. This project is an excellent demonstration of the intrinsic beauty of mill finish aluminium and its flexibility in fabrication. Form is an immutable part of architecture and the past decade has seen an increased exploration of radical geometries facilitated by digital design. The bespoke developed cladding system is technically smart but pragmatic in its application of technology, robust and cost effective, as well as stunningly beautiful.

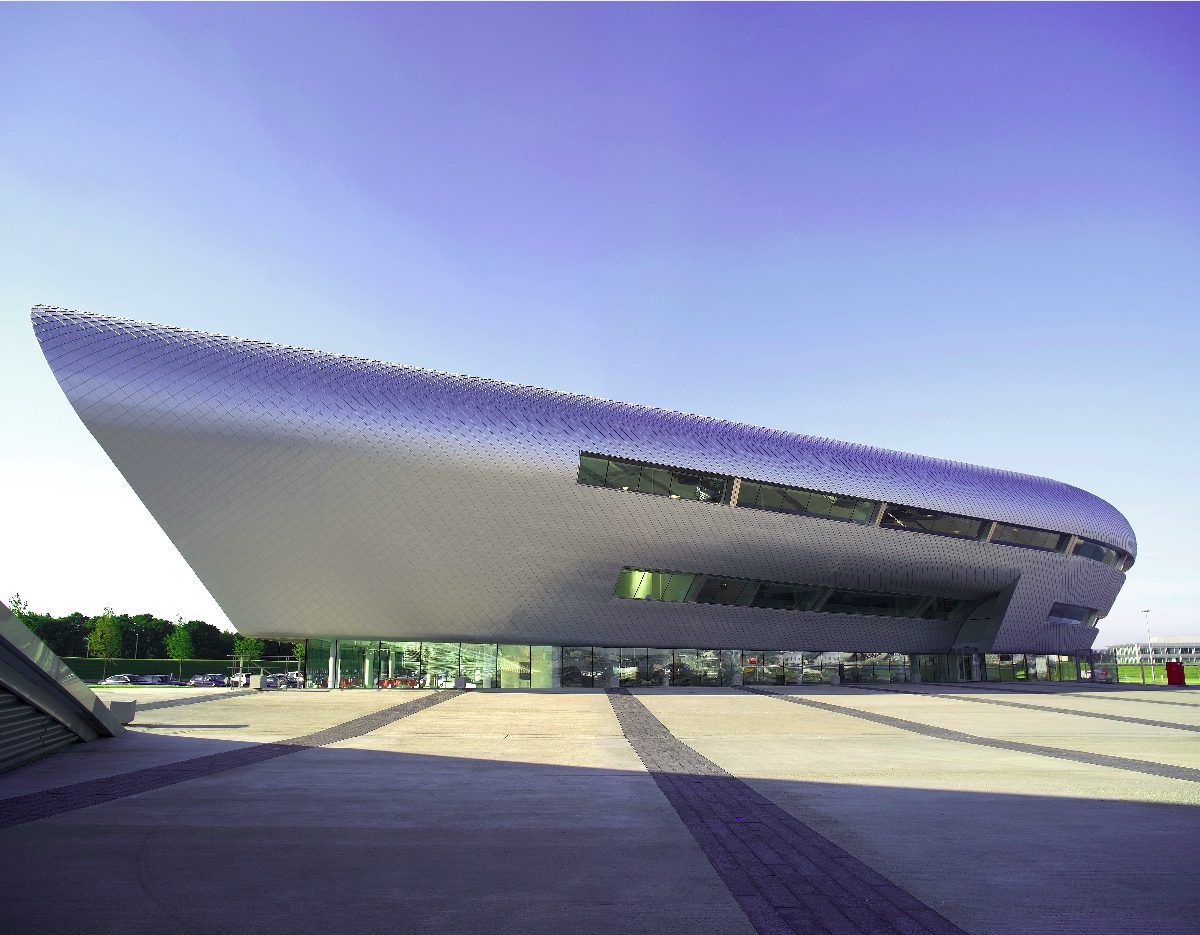

The Terminal has been conceived as a “wing” hovering over the landscape. The building walls and roof run seamlessly into each other to create a highly sculptural building giving constantly changing views when moving around it. The building is a long thin building cranked in the middle in order to maximise views from all parts of the building over the aircraft apron. The building form becomes an extension of the sweeping landscape bund, devised to screen the car parking spaces from the road and minimize visual clutter. Within this protected area is the taxi and public set down and pick up zone adjacent to the north entrance to the Terminal.

The building was constructed from materials and detailed in such a way as a reflection of aircraft technology. The main two storey “wing” is clad in natural mill finished aluminum panels (shingles), windows and roof lights will be detailed to create a smooth curved skin. The ground floor is predominantly glazed to generate the tension between the wing (the aluminum fuselage of the building form) and the ground plane.

Using a modified version of the rainscreen system used on the air traffic control tower, and incorporating a full vapour barrier, insulation and waterproof membrane build up, almost 25,000 million finished diamond shaped aluminium shingles were installed to the Façades, each interlocking with its adjoining shingles to provide the building’s unique skin.

The overlapping of the shingles give the interesting textured finish to the building when close up, yet a smooth uniform effect when viewed at a distance. The flexibility of the aluminium cladding enabled the continually changing contours of the building to be easily followed using standard shingles without the need for lengthy and expensive individual shingle design, fabrication or forming.

The huge overhanging ends of the building above the first floor terraces were clad using mill finished aluminium panels to match the feature panels on the ends of the buildings, and to provide a harmonious contrast to the shingle cladding to the rest of the building envelope. Mill finished aluminium panels also featured to the recesses of the ribbon windows as the transition between glass and shingle.

It was essential to develop the technical specifications for the final cladding solution in conjunction with the limited number of companies with the ability to do it to ensure the delivery of the concept for the aluminium cladding in a controlled manner that was fully worked out and to enable co-ordination with other more traditional packages. A pre-order for design was placed with Mero UK to enable detailed setting out for the purlins and also development of interfaces to ensure their technical and aesthetic factors. This also led to the use of a full scale mock up section being tested at Taylor Woodrow’s facilties in Leighton Buzzard.

The aluminium shingles are 100% recyclable and easily repaired. This bespoke developed cladding system is technically smart but pragmatic in its application of technology, robust and cost effective, as well as stunningly beautiful.